Completion of Ochiai the largest self propelled tea harvester OHC-W(MONSTER).We gather our company 100 year's know-how, experience and tequnique.This world wide standard model debut.

Body

Development history

Especially for companies that are engaged in plantation management, pursuing the profits of the company will protect the workers they employ. Demand for the introduction of large machines has increased as one of the means to pursue profits to protect the lives of currently engaged workers and their families.

* Japan Trade Statistics Survey (2020) Challenges The climate, environment, climate, everything is different from Japan. There are many large tea gardens that cannot be seen in Japan. Matching fields to Japanese machines is limited to only a few areas.

In order to meet more needs, it was essential to design and develop machines that match the Kenyan tea plantation environment. And in order to maximize work efficiency, it was required to make the machine larger than the domestic standard machine by 30% or more. Development A large machine that we have never experienced before. In addition, the frequency of local use is 10 times that of Japan, and all technologies have been applied to ensure the strength to withstand the local work time. We have taken great care to protect the safety of workers.

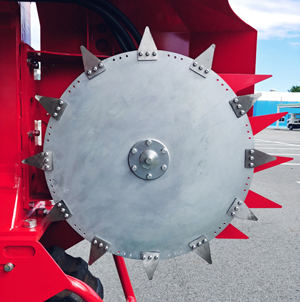

The project started in 2017. We have redesigned the concept and design by bringing together all the strengths of the passenger model development members. Even after the prototype was completed, we made improvements in response to local requests. Especially for side cutters, we have no experience of our company due to overseas needs, so we listened tolocal requests and repeatedly created our trials. Finally, in 2020, we have completed a machine that we can introduce to you. Future We believe that the demand for mechanization will continue to grow and develop.Our challenge is still in its infancy. We will continue to grasp local needs, steadily solve various problems one by one, and develop products for everyone involved in tea gardens.

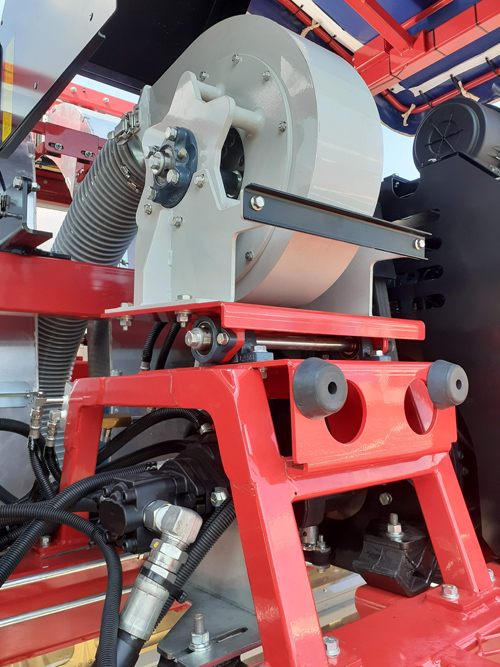

Running part

Plucking part

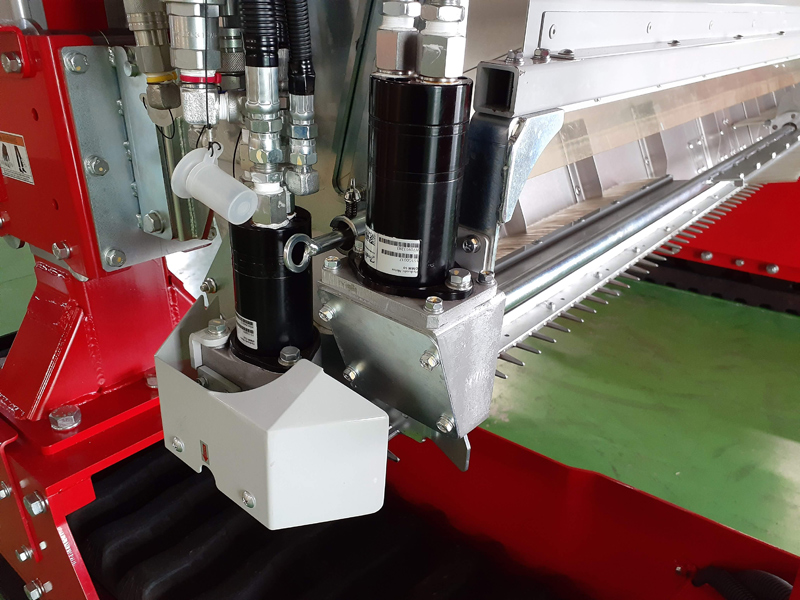

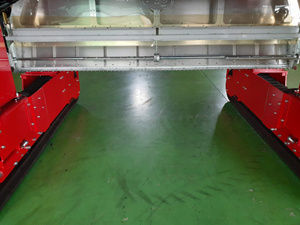

Blade

Blades are processed and produced in our own factory.Experienced craftworker produce it with gathering Ochiai secret tecqunique.Our blades have been supported Japanese tea plucking for more than 100 years.

Fan

Container

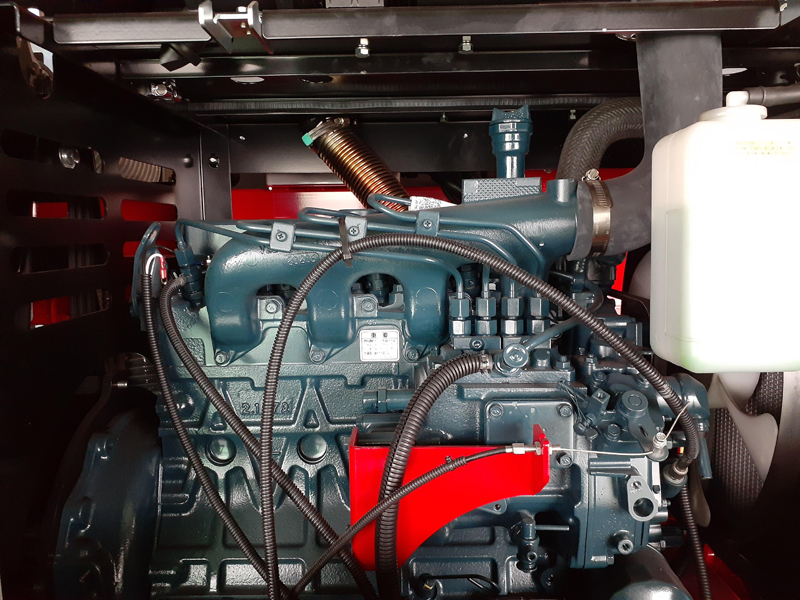

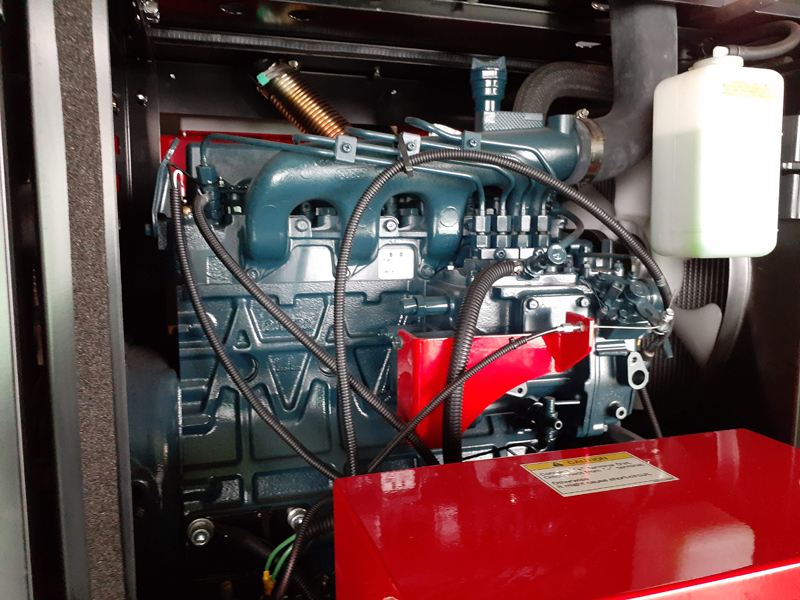

Engine

Driving sheet

Side cutter

Side cutter standard equipment.Cutting blanch while plucking operation.

Light

Specification

| NAME | SELF PROPELLED HARVESTER | ||

| GUAGE | (mm) | 2440(8feet)*7feet model also avaiable | |

| MACHINE DIMENTION | LENGTH | (mm) | 3470 |

| WIDTH | (mm) | 3140 | |

| HEIGHT | (mm) | 3340 | |

| WEIGHT | (kg) | 4200 | |

| ENGINE | OUTPUT | (kW (PS)/rpm) | 33.8 (46) / 2600 |

| TYPE | 4 CYCLE WATER COOLINIG 4 CYLINDER DIESEL ENGINE | ||

| DISPLACEMENT& FUEL CAPACITY | (cc)/(ℓ) | 2197CC / 53L | |

| RUNNING PART | SIZE: | (mm) | 320×90×58 (WIDTH×PITCH×LINK Q’TY) |

| SPEED | (km/h) | 0~3.6(FORWARD AND REVERSE) | |

| CUTTING PART | TYPE/BLADE TYPE | RECIPROCATING/HORIZONTAL | |

| CUTTINGE HEIGHT/LENGTH | (mm) | 700~1200/2429 | |

| CORRECTING | TYPE/TRANSPORT | CONTAINER/V BLOW SYSTEM | |

| CAPACITY | (㎥) | 4.3( APPROXIMATE 650kg) | |